|

| Bevels |

|

| Finest abrasives. | ||

| Microbevels front and back. | ||

| Use a jig. | ||

| Copyright (c) 2002-15, Brent Beach |

For most people, a cutting edge -- say a knife -- has two bevels. When first thinking about a plane blade, most people think it has only 1 bevel - forgetting that the back of the blade is also a bevel. As I spent more time looking at worn plane blades under the microscope, I came to the conclusion that the sharpest edge can only be produced using a series of abrasives, each producing its own bevel, on both the front and back of the blade. This pages discusses the issues involved. [Are these models confusing? Check out the introduction to Sketchup models that shows honed microbevels and wear bevels.]

The back of a new plane blade is more or less flat - it may be a little rough and have a few machining marks, but it is pretty flat. The bevel is also pretty flat. In some case, like recent Lee Valley blades, the back is very flat. You can hone the front (at the original angle or use microbevels) and use the blade. It will work pretty well. [In fact, Rob Cossman has a video on YouTube in which he does just this. Of course, this only works the first time you use a blade. After use, wear bevels on the back make this technique worthless. As such, the Cossman video is very misleading. I hope he tells people after this demo that it is just a trick, of no actual use to anyone.]

The back of a new plane blade is more or less flat - it may be a little rough and have a few machining marks, but it is pretty flat. The bevel is also pretty flat. In some case, like recent Lee Valley blades, the back is very flat. You can hone the front (at the original angle or use microbevels) and use the blade. It will work pretty well. [In fact, Rob Cossman has a video on YouTube in which he does just this. Of course, this only works the first time you use a blade. After use, wear bevels on the back make this technique worthless. As such, the Cossman video is very misleading. I hope he tells people after this demo that it is just a trick, of no actual use to anyone.]

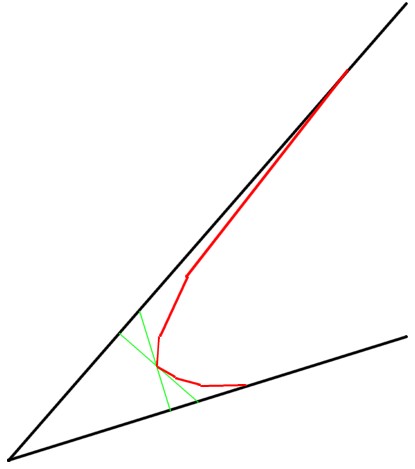

This sketchup model shows both the new and used shape of the blade - new on the left, used on the right. This model shows just the last 0.01" of the blade - a small part near the edge. The blade is shown in the orientation it has in the plane. In fact, the model assumes a bevel down iron, bedded at 45 degrees. It could just as well be a bevel up iron, bedded at 15 degrees.

The worn area of the blade - the wear bevel - is shown in red. The right edge of the intersection of the "as new" and worn shapes shows the amount of metal worn away during use. The amount the upper surface is out of flat is shown by the grey along the red. On a bevel down plane, this is the amount the back of the iron is now out of flat.

The amount the lower surface is out of flat is shown as well. On a bevel up plane, this is the amount the back of the iron is now out of flat.

When you sharpen this blade you have two options. First, you could try to return it to its original condition. Second, you try a sharpening approach that includes back bevels.

By original condition, I mean sharpen the blade so the back and front bevels are flat all the way to the edge. There are any number of ways of doing this, but these two drawings are typical.

By original condition, I mean sharpen the blade so the back and front bevels are flat all the way to the edge. There are any number of ways of doing this, but these two drawings are typical.

The first approach is to remove about as much metal from both sides of the blade, ending up with a new edge in the middle of the wear bevel.

Unfortunately, this involves removing a lot of metal. You would be removing about 0.005" thickness from the back of the iron. When an iron is only 0.1" thick, this is a problem, even if you could do it.

This is the more likely option - you grind the bevel back through the worn edge until you have ground off most of the back wear. Then you flatten the back, taking off much less metal than before. Unfortunately, you also shorten the iron quite a bit. You must also grind through the edge - that is, you must use your most aggressive abrasives at the tool edge. I believe you should only grind through the edge to remove damage to the edge or to reshape the edge. You should not make it part of every sharpening operation.

This is the more likely option - you grind the bevel back through the worn edge until you have ground off most of the back wear. Then you flatten the back, taking off much less metal than before. Unfortunately, you also shorten the iron quite a bit. You must also grind through the edge - that is, you must use your most aggressive abrasives at the tool edge. I believe you should only grind through the edge to remove damage to the edge or to reshape the edge. You should not make it part of every sharpening operation.

With that introduction to the sharpening problem, time for a review of the terminology.

It seems to me that the original condition is not a condition to which you can return. Rather, this drawing shows a new condition for your plane irons (and other edge tools) that is sharp. This blade will wear just the same, but you can quickly and easily return this blade to this condition.

It seems to me that the original condition is not a condition to which you can return. Rather, this drawing shows a new condition for your plane irons (and other edge tools) that is sharp. This blade will wear just the same, but you can quickly and easily return this blade to this condition.

The drawing lets you see both the upper and lower microbevels. The dark green is the first microbevel, the gold the second microbevel, the blue the third microbevel. The triangular tab at the left shows how much metal is removed going from one microbevel to the next. You cannot even see the slice removed during honing microbevel 3 in this drawing. Later drawings will show it clearly.

Primary BevelThe big bevel that everyone sees -- that is there when you buy a new iron -- is the main or primary bevel. Manufacturers usually recommend a primary bevel angle of about 25 degrees.The face of the iron that has the primary bevel is the FRONT of the iron; the other face is the BACK of the iron. (This is an arbitrary naming convention. Others use exactly the opposite terms.) Bevels on the front of the iron are also called front bevels, while bevels on the back are called back bevels. MicrobevelsGrinding is the process that creates the primary bevel. Once we have ground the primary bevel, we hone microbevels. We create these microbevels by very slightly increasing the honing angle and honing on a finer abrasive. At each step we remove the scratches left by the earlier grit, while putting on new finer scratches.I use three abrasives - 15, 5, and 0.5 micron - to put three microbevels at ever increasing angles. The result is an edge that has been honed on both sides using an extremely fine abrasive. What is more, the process has removed all of the scratches from earlier grits in the region at the edge where all contact with the wood takes place. Microbevels as a sharpening technique have been around for a long time. In fact, the very first issue of Fine Woodworking January 1976 included an article by Bruce Hoadley "Micro bevels; getting a better edge." This article is available on the Fine Woodworking website. [Note: The article is wrong in asserting that the microbevel does not affect chip formation. In fact, all contact between the wood and the blade takes place on the front and back microbevels.] Leonard Lee also mentions micro bevels in his 1996 book. Wear BevelsThese are all good bevels produced during sharpening. The bad bevels, the wear bevels, are produced during use.If you have never seen pictures taken by the QX3 microscope, you should read the short introduction to the QX3 microscope and the pictures it takes. That article includes some images of razor blades. Most microscope pictures of cutting edges show just the sharpened edge. I am going to show you sharpened and worn edges. This discussion is based on using bevel down planes - normal bench planes. That means that the front bevel faces down toward the work during use, while the back bevel faces forward toward the shaving. |

|

|

This is a freshly sharpened blade, front side, showing the 4 bevels, with the edge at the top.

The third microbevel, labelled 32 degrees and produced using 0.5 micron abrasive, is the dark area at the edge. This area looks like it is scratch free because the scratches left by the 0.5 micron abrasive are too narrow to reflect light. I am still looking for an electron microscope to get an image of these scratches. This microbevel is about 0.0045" wide. The second microbevel, labelled 31 degrees and produced using 5 micron abrasive, has fine scratches going up to the left. Of course, immediately after honing this microbevel these scratches went right to the edge and this microbevel was about 0.01" wide. The last honing step removes the part of the second microbevel at the edge, while producing the third microbevel. The first microbevel, labelled 29 degrees and produced using 15 micron abrasive, has deeper scratches going up to the right. Immediately after honing this microbevel, these scratches went right to the edge and this microbevel was about 0.025" wide (under 1/32"). The primary bevel, labelled 25 degrees with rough scratches going up to the left, is at the bottom of this picture. I usually grind the primary bevel using a coarse Silicon Carbide bench stone. |

|

|

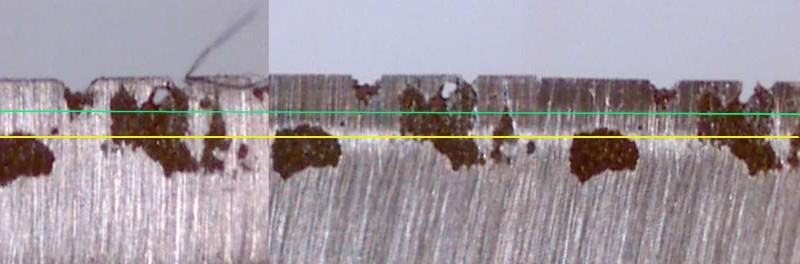

This is an image of the microbevels on the back of a freshly sharpened blade.

The area labelled 3 is the third microbevel, produced using 0.5 micron abrasive. For a typical blade this microbevel is at an angle of around 4.3 degrees to the back. The area labelled 2, with scratches slightly angled up to the right, is the second microbevel, produced using 5 micron abrasive. For a typical blade this microbevel is at an angle of around 3.4 degrees. The area labelled 1, with near vertical scratches, is the first microbevel, produced using 15 micron abrasive. For a typical blade, this microbevel is at an angle of around 2.4 degrees to the back. |

|

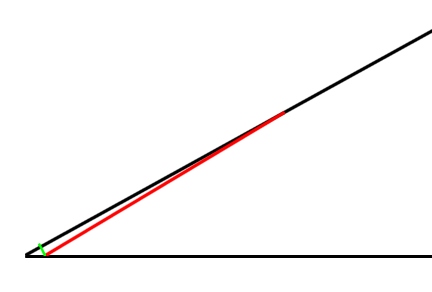

Using the dimensions from the above images, this is a scale drawing of the primary bevel - in black - with the first microbevel shown in green.

Using the dimensions from the above images, this is a scale drawing of the primary bevel - in black - with the first microbevel shown in green.

You will notice that the first microbevel has honed a very small portion of the primary bevel. The primary bevel is 0.22" wide, the microbevel only 0.025" wide. The depth of metal removed at the edge is calculated to be 0.00174".

To remove that much metal over the entire primary bevel would mean removing almost 16 times as much metal. That is, it would take 16 times as long and wear out 16 times as much abrasive.

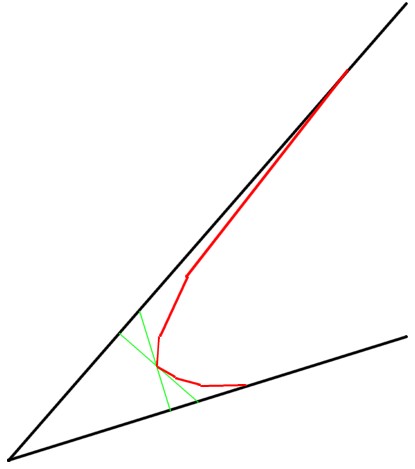

This is a scale drawing (equivalent to about 300 times magnification), of the tip of a plane blade - the 0.01" at the tip. The blade is drawn as if it was back down, edge facing left with the front side microbevel facing up. The black lines represent the blade with a 29 degree included angle. This is the situation after the first microbevel.

This is a scale drawing (equivalent to about 300 times magnification), of the tip of a plane blade - the 0.01" at the tip. The blade is drawn as if it was back down, edge facing left with the front side microbevel facing up. The black lines represent the blade with a 29 degree included angle. This is the situation after the first microbevel.

The red line shows the second microbevel, at 31 degrees.

The very short green line shows the depth of the metal removed in honing this second microbevel.

The scale was selected based on the second microbevel being 0.01" wide (a typical value).

The depth of metal removed is then 0.00035". (The blade is shortened by 0.00076".)

This depth of metal removed is actually an important number. The widest scratch left by the 15 micron abrasive used to create the 29 degree microbevel is about 0.0003". If we assume the depth is about half the width (the abrasive crystals are roughly cubical so the corners are about 90 degrees), then the deepest scratch is about 0.00015".

The metal removed at the edge during honing of the second microbevel is over twice the depth of the deepest scratch in the first microbevel. I have been told that the damage to the metal during abrasion is not restricted to the scratched up surface, but extends to about twice the depth of the scratches into the surface. With this geometry, the second microbevel removes all metal damaged during the honing of the first microbevel. Of course, it causes some more damage itself (which gets removed in the next step ...).

|

The angles I use when sharpening, combined with the jig size and the thickness of the slips are not selected at random!

With reasonable care, using these standard angles and sizes, you will produce perfect microbevels, and the best possible edge while removing the minimum amount of steel from your blade. |

An interesting article on Gemstone polishing includes a drawing of how depth of scratch affects the scratched material, reproduced on the right. This article is well worth reading if you are interested in the detailed mechanisms of sharpening.

An interesting article on Gemstone polishing includes a drawing of how depth of scratch affects the scratched material, reproduced on the right. This article is well worth reading if you are interested in the detailed mechanisms of sharpening.

The article is about polishing gemstones, using results derived primarily from scratching glass, but some of the concepts may well carry over to honing tool steels. The article cites literature which describes three different models of the polishing process. First, the finer scratch model in which a decreasing series of grits are used, producing finer and finer scratches until the scratches can no longer be seen. I have assumed this model. Second, for very fine abrasives, the metal on the surface is smoothed by the grits rather than chipped away (a plastic process, like modelling clay or perhaps raking a garden). Third, for some polishing with grits in flexible media (stropping), a chemical reaction (involving the metal, the abrasive and the other components of the polish) occurs that removes material atom by atom.

Whatever model you use, there appear to be different processes involved for grits size 1 micron and smaller than for grits 20 microns or larger (in between, it may be a combination of the two). For scratches less than 1 micron deep, the grits move material around on the surface without cracking the subsurface. For scratches up to 10 microns deep, cracking occurs radially from the groove, with little damage below the scratched surface. For scratches over 10 microns deep, cracking can occur well below the bottom of the groove.

For sharpening edge tools, assuming the results from glass and gemstones carry over to tool steels, the implications are clear. Use of large grit abrasives (possibly even small grit abrasives at very high speeds) will damage the metal below the surface. However, use of fine abrasives at low speeds will not alter the internal structure of the edge.

The article reports another unexpected observation -- use of very fine grits creates considerable stress in the surface. It has long been known that hammering a saw spreads the metal on the surface, creating tension in the saw blade. Chipping bits off with large grits leaves no stress, but rubbing the surface metal around with very small grits leaves unresolved stress in a very thin layer of metal on the surface.

If stresses are created during the last honing step, the third microbevel, do they affect the durability of the edge? Given that this surface layer is quickly worn away in use, does this matter at all? Unlike gemstone polishing where the surface left by polishing is the final surface, in plane blade sharpening, the surface produced by honing is quickly worn away (the top micron or so anyway).

If you read this article and have any opinions on it, on my interpretation of it, or on information about the effect of abrasives on steel as discussed in any of the articles the gemstone article cites, I would be interested in hearing your views.

|

This section was written in 2006, long before I read Leonard Samuels' books on Metallography. The points made here are roughly true - the ideas to apply to both gemstones and tools steels. The state of the metallographic art is beyond what was know to the author of the above article.

A slightly different explanation of this material also appears in Grinding, Keeping Your Edge, Grinding shatters the metal at the edge. |

OK, enough about freshly sharpened blades. We can now turn our attention to worn blades.

OK, enough about freshly sharpened blades. We can now turn our attention to worn blades.

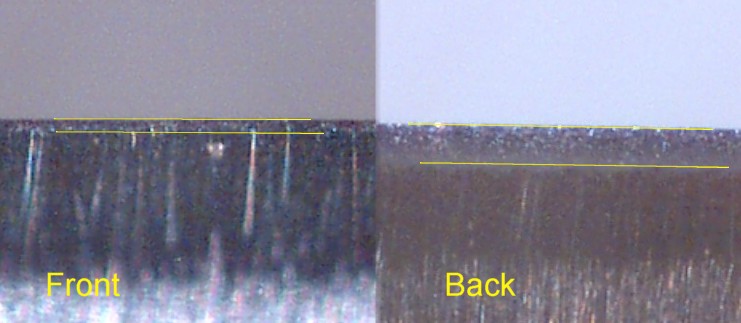

When you use a plane, the cutting edge pushes forward and down against the wood. The upper surface of the iron pushes against the shaving, pushing the shaving up and through the mouth. The lower surface of the iron pushes down against the work. The action of the wood on the iron actually grinds/hones metal away, producing what I call a wear bevel on both upper and lower surfaces. These pictures show both the front and back wear bevels.

This discussion applies equally to bevel down (normal bench planes) and bevel up (block planes, some bench planes) irons. It is important then to use names that do not depend on whether the bevel faces up or down. I use upper wear bevel for the wear bevel on the blade face which is upward during use - pushing the shaving up through the throat. Likewise, lower wear bevel applies to the wear bevel on the downward blade face which rubs against the work.

It happens that this is a bevel down iron, so the face labelled front faces down toward the work and has the lower wear bevel. The face labelled back faces up toward the shaving and has the upper wear bevel. It is typical that the upper wear bevel is the wider of the two by about this factor. [On a bevel up plane, the wide wear bevel occurs on the front of the iron!]

The area between the yellow lines is the wear bevel. The lower wear bevel is about 10 pixels or 0.0007" wide, the upper wear bevel is about 40 pixels or 0.0028" wide. The iron itself is actually shortened by about 0.0002" during use. This wear was the result of 200 passes along a 4 foot douglas-fir board.

These wear bevels are visible without magnification. If you hold a worn iron toward a light and tilt the blade back and forth, you will see a bright line along the edge. The angle at the edge between the line from the edge to the light and the edge to your eye should be about 90 degrees. Wear bevels are visible on both the front and back of a worn blade.

This is a scale drawing of a worn blade, based on observed test results. This interpretation is new as of Mar, 2006.

This is a scale drawing of a worn blade, based on observed test results. This interpretation is new as of Mar, 2006.

This time the blade is drawn as it would be in the plane. This plane has a bedding angle of 46.5 degrees. The blade was sharpened with a single front microbevel at 29 degrees, and a single back microbevel at 2.4 degrees. That is, the included angle was 31.4 degrees.

The black outer lines show the original microbevels. Once again the drawing is of the last 0.01" of the blade. The lower face (the clearance angle) is at 46.5 - 29 or 17.5 degrees. The upper face is at 46.5 + 2.4 or 48.9 degrees. The included angle is 31.4 degrees.

Before the test, each freshly sharpened face was scratched and the distance from certain features on the scratch and the sharp edge measured carefully. After the test (150 passes along the 4 foot test board) the distance from the same features on the scratch to the worn edge was measured. The shortening of the blade was 0.0013" (17 pixels), as measured on both the front and the back.

The green lines represent the observed shortening of the blade. The green lines are perpendicular to the faces because the microscope was perpendicular to the faces.

The worn edge must be at the intersection of these two green lines.

The width of the wear bevels was also measured. The wear bevel on the lower face was 0.00061" (8 pixels) wide, on the upper wear bevel almost 0.003" (40 pixels). So, we know where the wear bevels begin and end.

What do they look like between those points? In fact, I don't know. The red lines in the drawing are my current guess at the shape of the wear bevels.

This is a big change in my understanding of the shape of the wear bevels. I used to think the wear bevels were flatter, coming to a finer point with a smaller included angle than in this drawing. In fact, what you would get if you used steeper front and back microbevels. I now think the worn edge is blunt.

How blunt? If you use my jig when honing, you get a sharp blade as shown by the outer black line. The edge has thickness very nearly zero - it is sharp. At the point shown in this image, the worn edge has a radius of curvature of about 0.0005" (computed from the measurements above).

This is actually a 10 to 1 scale drawing of the 200X images taken of the test blade. This drawing corresponds to a magnification of about 2,000 times.

This is a scale drawing of a worn blade that started out with 3 microbevels on the front and back. It is the same wear profile as above.

This is a scale drawing of a worn blade that started out with 3 microbevels on the front and back. It is the same wear profile as above.

The bevels, starting from the edge: red is the wear bevel, blue is the remnant of the third microbevel, gold is the remnant of the second microbevel, green is the remnant of the first microbevel.

This zoomed drawing shows the amount of metal removed at each stage.

This zoomed drawing shows the amount of metal removed at each stage.

A few thoughts about the upper wear bevel.

While wider than the lower wear bevel, the upper wear bevel appears to be much flatter. I cannot measure the exact shape, but it appears that the slope of the upper wear bevel near the edge is no more than a few degrees different from the last honed bevel. So, wear on the upper surface does not greatly affect the geometry of the planing action. The small change however might make the plane work a little better on hard woods, a little worse on soft or stringy woods.

The worn upper surface is rougher than a freshly sharpened surface and at a slightly different angle than it was before use. Does this roughness affect the planed surface? Does sharpening remove this roughness?

Standard sharpening practice works the back face in two different ways. First, most people flatten an inch or so of the back near the edge before the first use of the blade. Second, most people lap the back of the iron (often more than once) during each sharpening operation to remove the wire edge.

Are they smoothing this wear bevel each time they sharpen? I believe the answer is no, particularly if they lap with the blade flat on the abrasive. The only way to smooth the wear bevel on the back using this sharpening protocol is to grind the blade down the full length of the back wear bevel. Put another way, you cannot simply grind up to the worn edge. You must continue grinding until you have ground away the entire back wear bevel.

Getting the best edge must involve smoothing the upper wear bevel during each sharpening operation.

While wider than the lower wear bevel, the upper wear bevel is still quite narrow - no more than 0.004" wide. This means that all forceful contact between the shaving and the iron takes place within 0.004" of the edge. Even if you could operate the plane with the cap iron set 1/32" from the edge, this is still 8 times too far away for the cap iron to have any effect on bending and breaking the shaving.

It is my belief that the cap iron, as typically set, plays no part in breaking the shaving (it is still important for operation of the plane in certain plane designs). In most Bailey style planes, moving the cap iron close enough to the edge to have an effect in chip breaking is not possible - shavings would jam in the mouth of the plane.

A study of chip formation in front of a mechanized planer confirms this view. It showed that chip breakers set between 0.004 and 0.002" from the edge do improve surface quality. [This page disappeared in early 2005, but is mirrored on Steve Elliott's blade testing pages].

This study was done with a power planer. These planers have no equivalent of the front of the mouth pressing the fibres down in front of the blade. Even without the front of mouth equivalent downward pressure, the use of the very close cap iron was able to reduce tearout. This suggests that the same features could work in hand planes - wide mouth, very close cap iron. That is, open the mouth to avoid jamming, cap iron very close to the edge to reduce tearout.

| May 2012 |

| Steve Elliot and Bill Tindall have managed to get a translation of the original paper. The translated paper, titled The influence of the cap iron, by Chutaro Kato and Yasunori Kawai is on Steve's site. Here is the translated video which shows shavings being formed with a variety of cap iron shapes and positions. |

| Figure 5 in that paper shows the cap iron wear! With the cap iron very close to the edge there is significant wear in the cap iron. I don't recall anyone reporting cap iron wear with a hand plane. This is yet another reason to conclude that in normal use, the cap iron is not turning the shaving - the shaving has already been broken by the blade. |

One of the important benefits of using a cap iron may be its ability to remove heat from the area of the edge.

The rate of wear is a function of the temperature of the steel at the edge, with cooler blades wearing more slowly. You can feel that heat is being generated from the temperature of the shaving. It is a little harder to feel the temperature of the iron, but if you remove the blade quickly after a shaving session, you can feel the warmth there.

This heat travels down the iron, with some being picked up by the cap iron. A heavier cap iron with a greater surface area in contact with the blade will remove more heat, allowing the edge itself to run a little cooler. The smoother the contact surface (between the blade and the cap iron) is, the more heat will be transferred. It makes sense then to check the contact surface.

It might be interesting to repeat a test with a heat insulator between the cap iron and the blade - say a thin shaving.

I have read reports of a technique that may smooth the back wear bevel, for those who don't use back bevels.

The idea is that rather than just lapping the back with the blade flat on the abrasive, you elevate the other end of the blade slightly. Charlesworth apparently uses a thin ruler along his sharpening stone. With the blade perpendicular to the ruler, he slides the blade back and forth on the stone. This is done as the final step, so only the highest grit is used.

The actual geometry is a little surprising. If you have a 2" wide stone and a 1/64" thick ruler, the distance between the edge of the ruler and the blade edge will be about 1-1/2", perhaps a little less. The microbevel angle will be about 0.6 degrees. If you remove 0.001" of metal perpendicular to the back at the edge, the microbevel will be 0.096" wide.

This should be enough to flatten the back (no other back flattening should be required). Because you are using a very high grit and working right at the edge, you should have a very good edge, the first time you use the iron. Since the wear bevel is only 0.0028" wide, this microbevel appears to solve the problem of honing away the wear bevel. I write appears because I have some unresolved questions about the exact geometry on subsequent sharpenings. [To do: Complete analysis of back wear bevel geometry through a series of sharpenings.]

|

David Charlesworth writes: "The ruler is stuck to one long edge of the 8000 or 10000 grit water-stone,

but the blade is moved across the stone not lengthwise, thus imposing scratches

at right angles to the edge, and hopefully honing away the last vestige of

wire edge!."

Moving the blade across the stone means that the honed bevel is an arc, not a flat. When I asked David about this, he replied: "I use a very short stroke, probably no more than 3/4 inch. The ruler is on one edge of the stone and the edge of plane blade moves on and off the opposite edge. {This avoids the hollow water-stone menace!} This is imposing a negligible back bevel of about 2/3 of a degree. Yes it must be infinitesimally curved, but not significantly. The width of this polished 'bevel', is about 1/32" to 1/16" and stays the same for the life of a blade." An interesting approach. I may try this myself some day to see how well it works. Perhaps I can get a microscope image of the resulting back bevel. Lie-Nielsen sells a video made by David which demonstrates this technique. |

Performance Impact

How much can smoothing the back wear bevel every time you sharpen improve plane performance? Tough question, but I would guess that the effect is small. I have taken pictures of back bevels after 50, 100, 150, and 200 passes along the 4' board. The wear bevel gradually widens as the test goes on. So, the back wear bevel is there almost as soon as you start planing. What benefits there are probably show up during the first few planing passes - something probably only important for final smoothing of difficult grain. [To do: Test blade using normal sharpening, then retest same blade without honing the wear bevel.]

So, if you do not use back microbevels, you will have a bit of back wear bevel on your freshly sharpened blade.

This means that most plane users are planing with an angle at the shaving of greater than 45 degrees. Most of the time their planes perform well with this slightly higher planing angle.

It depends on the included angle and perhaps the bedding and clearance angles to a small degree, but basically every worn blade will look like this right at the edge, no matter what its original geometry was. That is, with or without an original back micro bevel, it will have a back wear bevel during use!

As soon as you start planing, the blade shape begins to morph from the sharp blade shape to the worn blade shape. Most of the time the blade looks more like a worn blade than a sharp blade.

Most of the time you will be planing with a back wear bevel.

The lower surface of the iron rubs against the work. This rubbing has the effect of gradually grinding/honing a new bevel on the lower face of the iron. As more metal is ground/honed off, the wear bevel widens.

The lower surface of the iron rubs against the work. This rubbing has the effect of gradually grinding/honing a new bevel on the lower face of the iron. As more metal is ground/honed off, the wear bevel widens.

Let's use the above drawing of a worn blade, where the red lines are my best guess at the shape of the wear bevels.

The first thing to recognize is that the lower wear bevel is where all the contact between the blade and the work take place. The upper wear bevel is where all the contact between the blade and the shaving takes place.

As the two wear bevels widen and the included angle grows, the plane stops cutting easily.

There appear to be two reasons for the poorer cutting action. First, the larger included angle means a blunter cutter. Don't let the scale of this image confuse the problem. In fact, the part of the dull edge that is actually cutting is probably less than 0.0004" wide. This is still a pretty fine cutting tool.

Second, the shape of the lower wear bevel. As you push the plane forward it tends to surf along the wood - to rise up out of the wood. As the lower wear bevel widens, this tendency increases. The person using the plane notices this and increases the downward pressure. This works for a while, but with increased pressure you also get increased friction, leading to increased heat and increased wear rate.

The difference in planing action as the blade goes from very sharp to too dull to use:

A freshly sharpened blade has an edge that is very very thin - too thin to see even at 200 times magnification. A surface 1 pixel wide at 200 times magnification is visible with this microscope. Since there is no visible surface area to the edge, the edge width is less than 1 pixel wide - less than 0.00007" wide.

I believe the edge is much less than this minimum visible width. Assuming the lower face of the edge is about half this width or 0.000035" wide, then the surface area of a 2" wide sharp iron edge is 0.00007 square inches. If you exert a downward force of only 1 pound, the force the edge itself applies to the wood is over 14000 pounds per square inch. The wood easily deforms under this pressure, which is why a reasonably heavy plane with a sharp iron and a flat sole can take shavings with no additional downward force.

During use, the lower wear bevel forms. After even one pass, I believe there is a very narrow wear bevel right at the edge with clearance angle of zero degrees. The plane still cuts and cuts well. The wear bevel is so narrow that the area of the surface pressing down on the wood is still very small. So, the effective pressure is still very high. With any forward movement, the blade is easily driven down through the fibres.

However, as the width of the wear bevel increases, the plane performance decreases. It is hard to tell the difference in performance between a freshly sharpened plane and one with a wear bevel up to 2 or 3 pixels wide. When the wear bevel reaches 6 pixels (0.00043") the plane still works reasonably well, but you can tell the difference.

When the lower wear bevel reaches a width of 8 to 10 pixels, the surface area of the lower face is at least 16 to 20 times as great as that of a freshly sharpened blade. The pressure the iron exerts on the wood is reduced by the same factor. Instead of 14000 pounds per square inch, the effective pressure is between 700 and 875 pounds per square inch. With this decreased pressure, the iron is no longer able to press into the wood fibres.

Increasing the pressure on the plane by just pressing harder does not work very well. As pressure increases, the plane and the surface supporting the work deform a little. The plane deformation (frog, cap iron, lever cap) results in a reduction in blade set. The work surface deformation results in a sag in the bench top. As well, increased effort seems to result in a reduced ability to sense what the plane is doing and get feedback from the wood. Eventually, usually a few passes later than optimal, you have to resharpen the blade to remove the lower wear bevel.

Most people sharpen bevel up irons no differently than bevel down irons - they sharpen the main bevel. I think this is a mistake.

In this drawing, the iron is shown as it is used - the bevel side is the upper surface.

|

|

|

A sharpening strategy that works both faces would remove less metal -- it would be quicker, use up less abrasive, and increase blade life. If you hone a 3 degree back microbevel, working until you had removed all of the lower wear bevel, you would solve this problem while removing far less metal and not actually shortening the blade.

In this drawing, the yellow line represents the 3 degree back bevel. Do not be misled by the small apparent difference between the lower wear bevel (red line) and the new lower microbevel (yellow line). The lower wear bevel was drawn as a flat surface at about 5 degrees. In fact, it should be a curved surface with the part near the edge horizontal. By working both the front and the back of the iron at the edge, you can reduce the amount of metal you remove during sharpening by a factor of 10. As well, if you were able to do this perfectly, you would not actually shorten the iron at all during sharpening. This ten-fold improvement is sharpening efficiency for bevel up irons has no parallel for bevel down irons. In the bevel down case, the wear bevel that must be removed is on the main bevel. It is readily removed using standard sharpening techniques. As shown above, the wear bevel on the back is not removed using standard sharpening practice, but that is not as important.

|

|

| Pitch | Angle |

| Common | 45 |

| York | 50 |

| Middle | 55 |

| Half | 60 |

If you are getting tearout problems you can increase the back bevel angle by making a jig with a taller short jaw. Assuming the tall jaw is 1.75" then you can use this table to find a short jaw height to create any desired back bevel. Or, you can make a wooden slip with thickness equal to the difference between the actual short jaw height and the height in the table. NOTE: The angle shown here is the final back bevel angle, assuming you use the two standard slips when honing the back bevel.

| Short jaw height | Back bevel angle | Effective angle |

| 1/8" | 3.6 degrees | 48.6 |

| 1/4" | 6 degrees | 51 |

| 3/8" | 8.1 degrees | 53.1 |

| 1/2" | 10.2 degrees | 55.2 |

| 5/8" | 12.2 degrees | 57.2 |

| 3/4" | 14.3 degrees | 59.3 |

| 7/8" | 16.3 degrees | 61.3 |

| NOTE I would dedicate an iron to a particular back bevel angle rather than using a single iron and changing the back bevel to suit the wood. While it is easy to increase the back bevel angle, it is much harder to decrease the back bevel angle. The proper procedure for removing a large back bevel is to grind the front primary bevel until the entire back bevel has been removed, then start honing. This is slow, involves regrinding through the existing edge, and shortens the blade. It is much better to dedicate a blade to the steeper back bevel. |

All pictures of the back microbevels at 60 times magnification (there are 3 pictures, but you have to look closely to see the join between 2 and 3). From 15 micron on left to 0.5 micron on the right. The yellow line shows the limit of the 5 micron microbevel; below that in pictures 2 and 3 it is remnant of the 15 micron microbevel. The green line shows the limit of the 0.5 micron microbevel; below that in picture 3 is the remnant of the 5 micron microbevel.

This blade worked very well, cut cleanly and lasted well, in spite of the small pitted area.

Check out my jig page for a simple jig you can make in your shop, along with a sharpening set up using sheet abrasives, that reliably produces excellent edges, for all types of irons.

Return to the Sharpening home page.