|

| ECE |

|

| Finest abrasives. | ||

| Microbevels front and back. | ||

| Use a jig. | ||

| Copyright (c) 2002-15, Brent Beach |

As with all my other tests, I honed three front and back bevels using 15, 5, and 0.5 micron 3M micro abrasive paper.

|

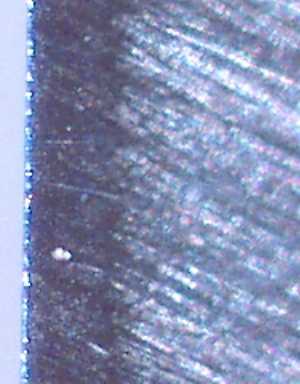

The front bevel, 200 X magnification, after the 0.5 micron paper.

In this sharpening, I twisted the jig to the direction of travel differently on each grit. In this lighting, the 15 micron scratches go up from right to left, the 5 micron scratches go up from left to right, and as usual the 0.5 micron scratches are not visible. |

|

|

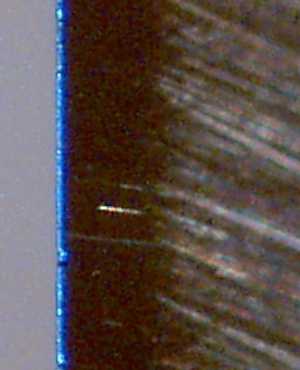

The front bevel, 200 X magnification, after 50 passes along 4 foot douglas-fir board. The wear bevel is about 8 pixels wide.

This picture shows the wear bevel, but it looks like the 5 micron scratches are no longer present. The exact placement of the external lighting source makes a big difference in which scratches are visible. In this case, the light position required to get the wear bevel to show up leaves the 5 micron scratches so poorly lit as to disappear. |

|

| The front bevel, 200 X magnification, after 100 passes. The wear bevel is about 10 pixels wide. |

|