|

| Lee Valley Block Plane |

|

| Finest abrasives. | ||

| Microbevels front and back. | ||

| Use a jig. | ||

| Copyright (c) 2002-15, Brent Beach |

This test is very different from other tests because this is a bevel up plane. See all kinds of bevels for a discussion wear bevels on bevel up planes.

As with all my other tests, I honed three front and back bevels using 15, 5, and 0.5 micron 3M micro abrasive paper.

Because this iron is used bevel up and the crucial wear bevel is therefore on the back of the blade, I am including two pictures at each stage: first the bevel side then the back side.

The back side has three microbevels, as with all the irons in this test. The back bevel closest to the edge has an angle of about 6 degrees. This reduces the clearance angle to 6 degrees.

|

The front bevel, 200 X magnification, after the 0.5 micron paper.

This is the side that will break the shaving. |

|

|

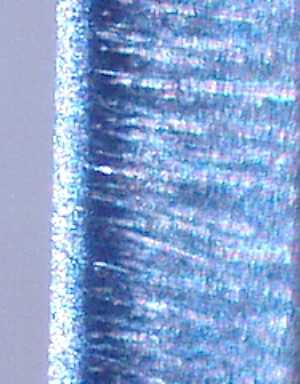

The back bevel, 200 X magnification, after the 0.5 micron paper.

This is the side that will rub along the work. |

|

|

The front bevel, 200 X magnification, after 50 passes along 4 foot douglas-fir board.

Remember this face just breaks the shaving. Quite a wide roughened area, but the edge is still smooth. |

|

|

The back bevel, 200 X magnification, after 50 passes along 4 foot douglas-fir board.

This face rubs on the work. The wear bevel is 7 pixels wide, the edge is still smooth. |

|

|

The front bevel, 200 X magnification, after 150 passes along 4 foot douglas-fir board.

This face just breaks the shaving. The upper wear bevel is quite wide, the edge shows a little breakdown. It is interesting that this upper face has about the same angle of attack on the shavings (12 degree bedding angle plus 32 degree bevel angle) and the width of the upper wear bevel is about the same, around 40 pixels or 0.003", as for bevel down planes. |

|

|

The back bevel, 200 X magnification, after 150 passes along 4 foot douglas-fir board.

This face rubs on the work. The wear bevel is 12 pixels wide, the edge has some curious defects. Even with this wide lower wear bevel, it was still possible to take thin shavings with this plane. I think that happens because of the rather small footprint of the plane. Downward force pushes the sole and the iron down. With the area of the sole being so much smaller, there is more downward force left over for the iron. Or, perhaps not! |

|