|

| Grinding - sheet abrasives |

|

| Finest abrasives. | ||

| Microbevels front and back. | ||

| Use a jig. | ||

| Copyright (c) 2002-15, Brent Beach |

|

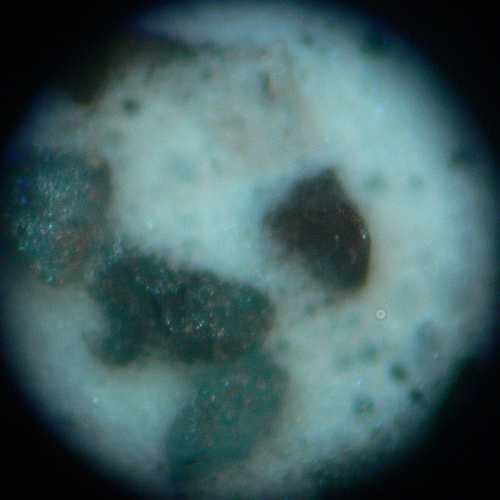

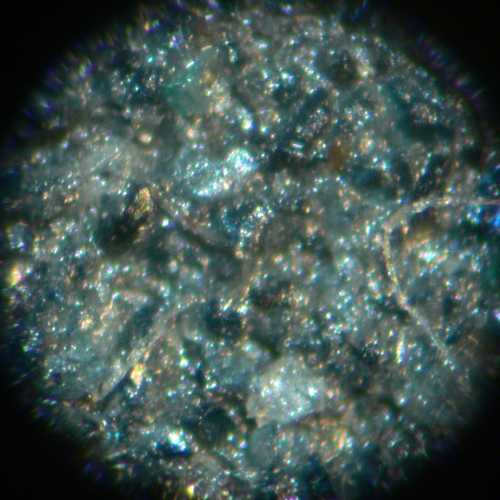

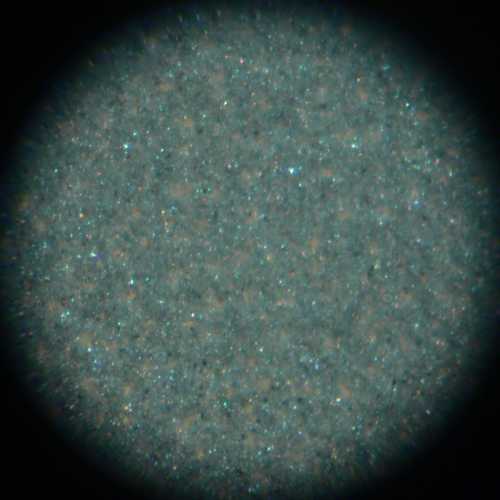

60 grit, Norton 3X

Average grit size 254 microns. Just looking at these 4 pieces of abrasive, it is pretty clear that the profile of the grit hitting the plane iron would be quite different depending on how the abrasive was glued to the backing paper. |

|

|

|

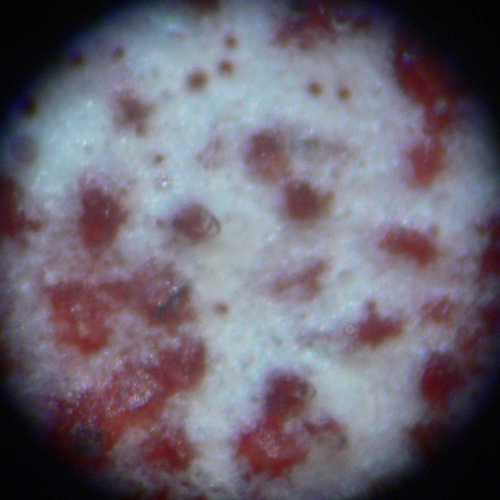

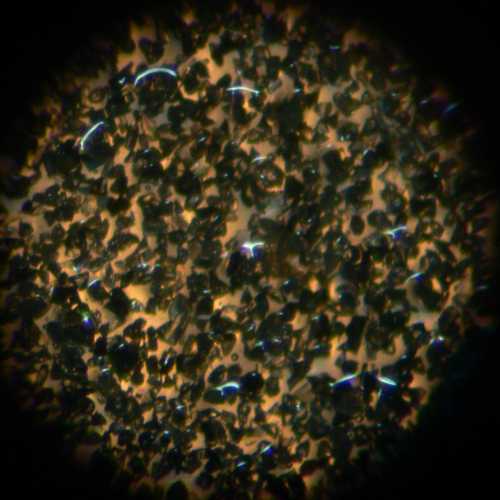

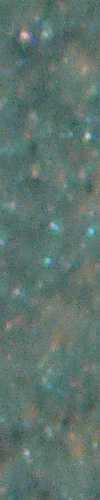

100 grit, Norton 3X

Average grit size 122 microns. Not sure why these particles are a different colour. Norton says they add no colouring to the abrasive - to prevent transfer to the object being sanded. Yet the four grits here are three different colours. |

|

|

|

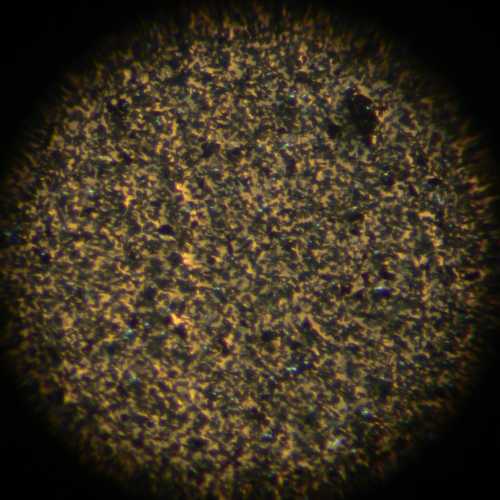

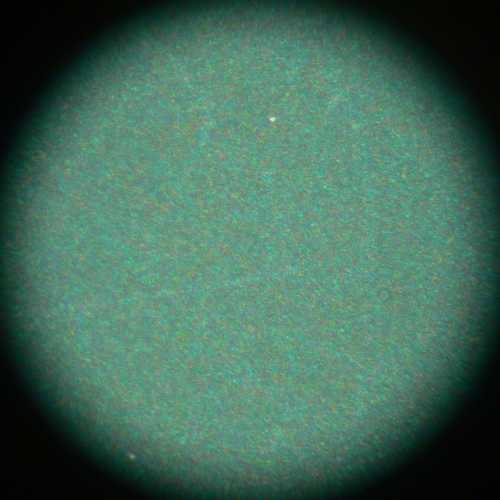

150 grit, Norton 3X

Average grit size 89 microns. |

|

|

|

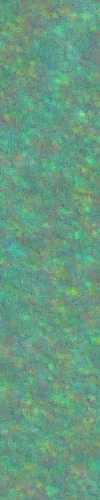

220 grit, Norton 3X

Average grit size 60 microns. More abrasive particles, but still nothing like the number of particles in the higher grits. Are there enough particles to reduce the chance of edge problems, but not so many that the grinding speed is too slow? |

|

|

|

Norton Coarse Silicon Carbide bench stone

A little hard to see individual grits, but clearly smaller than the Norton 3X 60 grit and larger than the 3M 40 micron. Could be about the size of the 200 grit, but there is less space between the particles. |

|

|

|

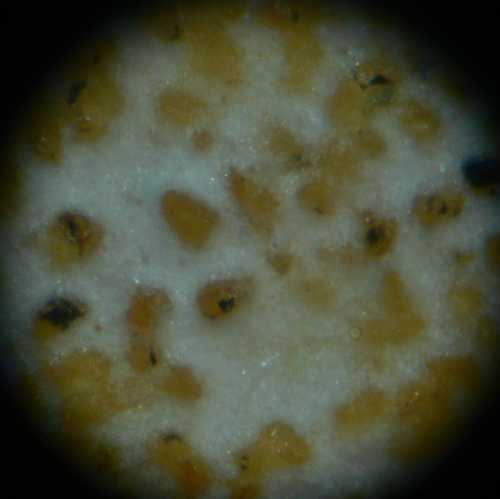

40 micron, 3M Microfinishing Film

Totally different size and grit count. It is easy to see the individual grit particles. The yellow colour is from a yellowish light shining through the clear backing, the glints from halogen light shining from above. |

|

|

|

15 micron, 3M Microfinishing Film

The grits are pretty clear, much smaller. The yellow colour is from a yellowish light shining through the clear backing. |

|

|

|

5 micron, 3M Microfinishing Film

The abrasive has clear backing, but there appear to be enough grits and glue that the paper is opaque. |

|

|

| 0.5 micron, 3M Microfinishing Film |

|

|